Pairing Application

Cox built an asset tracking platform that allows users to attach tracking devices to their important assets. Users need to associate assets with a specific tracking device, allowing them to later find the asset in the dashboard.

Current Landscape – What's Broken?

In the first weeks after founding, we created a simple pairing app. I no longer have the designs for it – it was all done on pen and paper and shipped within a week. We affectionately named this version "Boop de Boop" after the sound made by the hand scanners used in testing. Evenutally we opted to use cell phone cameras over hand scanners since most of our customers issued some sort of smart phone to employees. Eventually our customers began to out grow the simplicity of early versions. When talking with them, they expressed several concerns:

Too Many Clicks

Warehouse users can easily pair hundreds of assets a day. Every click and screen greatly impacts their workflow. Although warehouse employees responsible for pairing weren't our biggest champions, they were usually the loudest when things stopped working.

Increasing Data Complexity

Our early customers in the medical industry used standardized data (SKUs, Serial Numbers, etc.) with GS1 barcodes. This made initial implementation extremely easy since the inputs were predictable. As we expanded into manufacturing environments this was no longer true, so we needed to be more generous in what we accepted.

Enforcing Data Standards

User's also complained that finding assets in the dashboard was growing more complicated. We found this was directly tied to the growing data complexity and inconsistent naming of assets. While visiting one of our customers in Detroit, I found users were having difficulty understanding what to name an asset. Since they were not responsible for finding assets in the dashboard and their metrics were tied to processing shipments quickly, they would make their best guess and quickly move on.

Explored Solutions

Simplified Workflow

We can do several things to streamline the workflow when pairing/unpairing an asset

- The option to pair on unpair a tracker was completely removed. The app now checks if a tracker is active or inactive and automatically routes the user to the correct flow. This also solves the edge case for when user attempts to use a tracker that is already active.

- Scan multiple asset barcodes at once. Originally users had to scan each barcode individually. This worked fine if all of the data was stored in a single barcode (it was for our medical customers), but not so much with non-standardized data. Users can now scan multiple barcodes in one go, and the app will map the barcodes against the customer's preset data schema.

- Allow users to handle edge cases where barcode scanning is not possible. Sometimes data is not presented in a barcode format, or the light/label conditions make scanning impossible. A lot of this is technical work under the hood to improve scanning but also invovled streamline flows to make manualy data entry easier.

Enforce Data Types

Since the users pairing trackers are not the end user of the dashboard product, they do not always understand what data is important to capture. We can solve this by allowing admin users to designate required and optional data fields. Additionally, we can enforce certain formatting standards for specific data. The new app also can scan multiple barcodes in one go and automatically map them to a customer's data schema.

Auto Complete

We discovered many of our users have planning documents or BOMs that outline what assets they plan to consume. We can ingest these documents to enable autocomplete for manual entry. This also allowed us to enable suggest names, where we derive an asset name based on the inputted data. Inconsistent asset naming was the number one complaint of project managers using the platform.

Interaction Flows

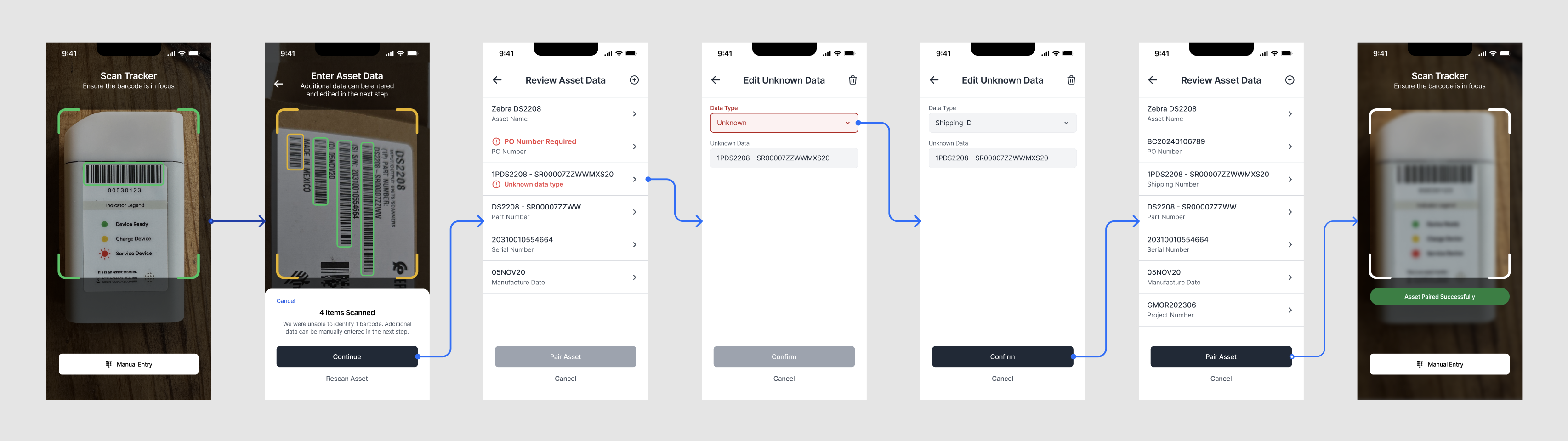

Pairing an Asset

We greatly simplified the workflow and number of screens required to pair an asset. If there are no errors, a user only sees three screens and clicks one button to successfully pair an asset.

Highlights

- Scan multiple barcodes and display decoding errors in real time. Additionally, users can move their camera around to capture barcodes on multiple sides of an asset

- Display data formatting errors earlier in the paring process, including highlighting missing required data fields.

- Allow users to manually add additional data. Sometimes additional data not displayed on the box of an asset needed to be entered

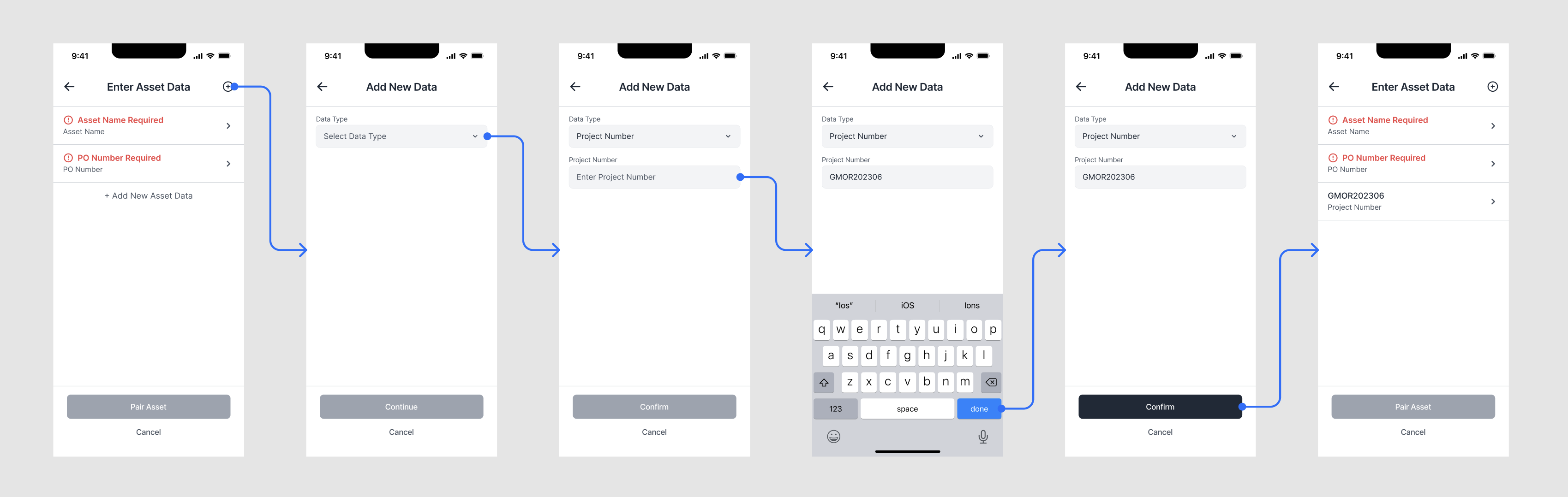

Manual Entry

There are edge cases where it is not possible to scan barcodes. We implemented a manual entry mode that allows users to bypass scanning.

Highlights

- Bypass scanning when a barcode is not available

- Autocompletion based on pre-uploaded data

- Derive Asset Name from user entered and pre-uploaded data

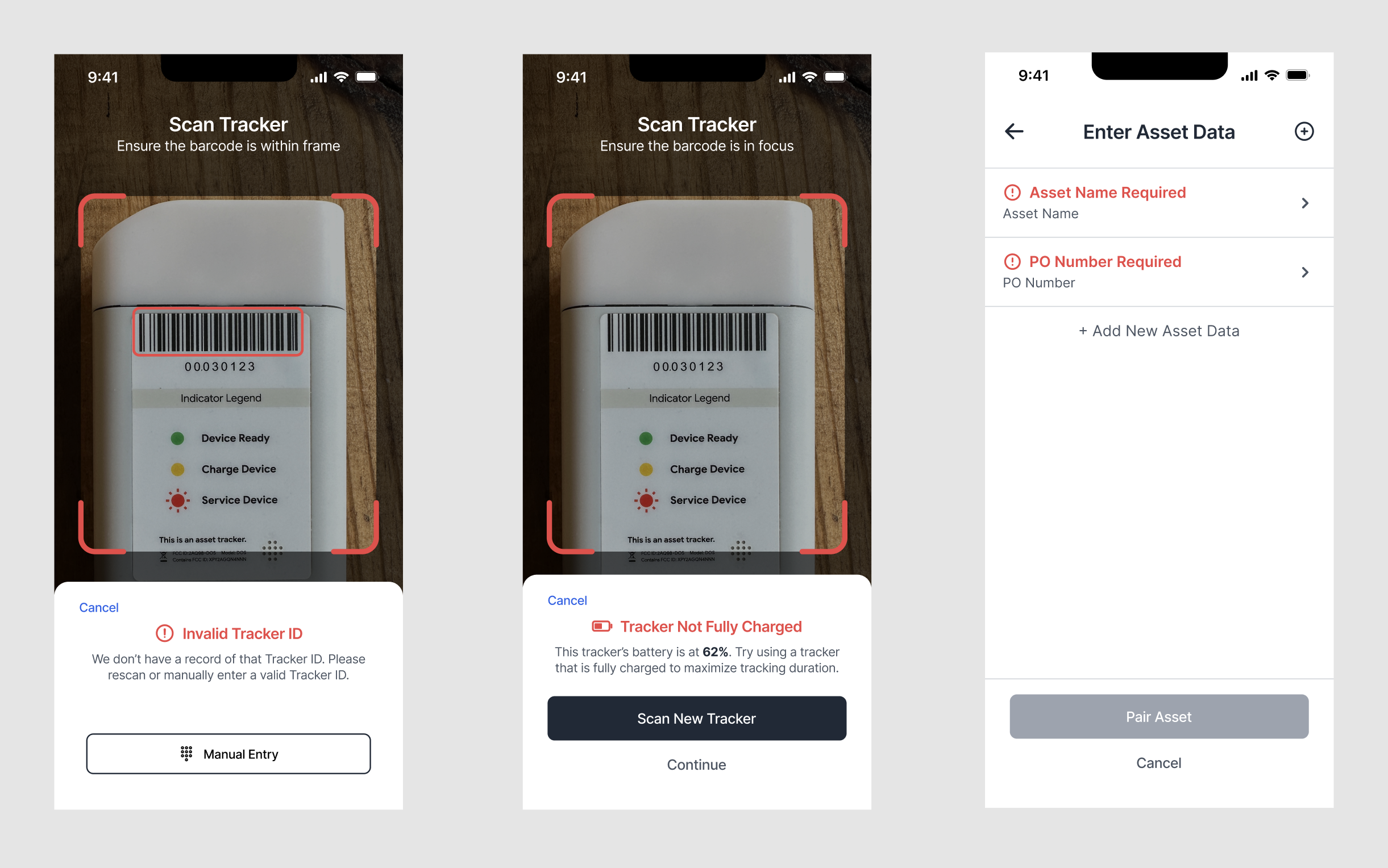

Catching Errors

Based on feedback from early releases, we shipped a few quality of life enhancements that catch problems earlier in the pairing process.

Highlights

- Highlight invalid tracker's at scanning rather than at form submission. We also ensure that trackers are assigned to a customer to handle cases where a tracker assigned to customer A gets accidentally sent to customer B.

- Check tracker battery life at pairing preventing instances where a low battery tracker is placed on an asset